The largest deposit of olivine in the U.S. is the Twin Sisters mine which sits high up in a mountain range of Whatcom County, Washington. This deposit contains over 200 billion metric tons (MT) of dunite (>90% olivine). Olivine ([Mg, Fe]2SiO4) is an established feedstock for carbon mineralization used by carbon dioxide removal (CDR) companies like Eion and Vesta in pilot and commercial projects.

To understand this feedstock’s potential within a regional ex situ mineralization system, the CC Lab team and collaborators constructed a parameterized LCA, and applied it to olivine from the Twin Sisters Mine. We are excited that our paper is now published in Environmental Science and Technology Journal. And with the publication, comes the LCA tool itself.

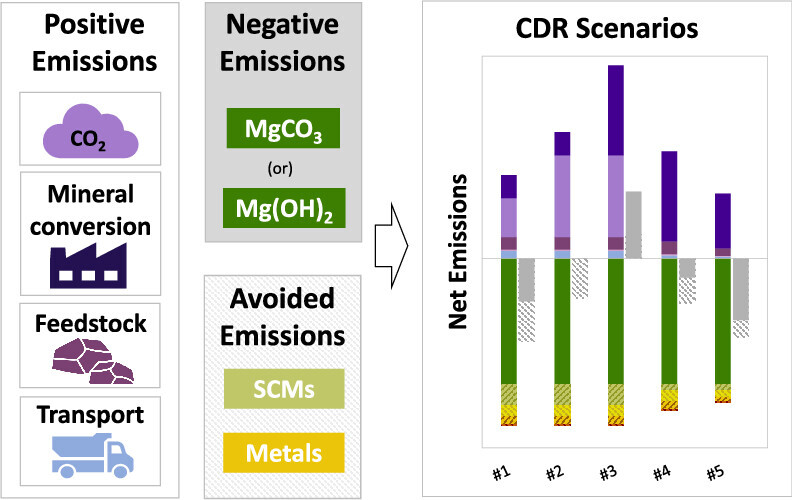

There are several potential mineralization pathways possible with olivine. We modeled a process where olivine reacts with CO2 sourced from three possible streams: 1) fossil CO2 from regional industrial point sources (like a nearby petroleum refinery), 2) CO2 removed via direct air capture (DAC), and 3) ambient CO2.

The resulting mineral products could be utilized by the regional cement industry (e.g. a cement terminal in Bellingham) to serve as supplementary cementitious materials (SCMs), thereby generating avoided emissions via the displacement of carbon-intensive Portland cement. (See Figure 1.)

.png)

Using the flexibility of our parameterized LCA tool, we were able to calculate and compare capture efficiencies for different reactor-based mineralization systems in this context that differed by CO2 source, mineralization pathway, scale, grid carbon intensity (2022 v 2050), and replacement ratio of SCMs in the cement manufacturing process. We also considered the potential for metal recovery.

We modelled the net emissions of different ex situ mineralization pathways when operating at the scale of 1 million MT of CO2 stored per year, with and without co-product utilization.1

We found that:

Ex situ mineralization systems vary widely in their capture efficiencies. Systems considered in this paper range from net CO2-positive to strongly net CO2-negative.

“Hotspots,” or particularly carbon intensive steps in the mineralization process, exist. CO2 capture (DAC; point source capture) and carbon mineralization processes contribute significantly to a system’s net emissions.

That said, predicted grid decarbonization through 2050 is predicted to reduce emissions penalties associated with energy intensive processes, sometimes dramatically. For example, DAC will drop in carbon intensity from 647 to 135 kg CO2e/MT CO2 stored with a cleaner grid.

Avoided emissions from co-product utilization can significantly improve the climate benefit of an ex situ mineralization system.

.png)

Matching scale to local markets

Results from this case study highlight how the capture efficiency of a reactor-based mineralization pathway is influenced by whether its scale of SCM production matches the uptake-capacity of the regional cement industry. Indeed, ex situ mineralization systems whose SCM co-products could be fully utilized by the cement industry could achieve capture efficiencies exceeding 100%. However, in the context of northern Washington, perfect SCM uptake was reserved for mineralization systems capturing no more than 100,000 kg CO2/year given the size of the cement industry there.

This illustrates a fundamental tradeoff in designing CDR systems: maximizing the capture efficiency of a reactor-based mineralization system requires constraining its scale to match the regional industrial demand for its co-products.

Furthermore, the economic and geopolitical significance of critical metal recovery from CDR systems should incentivize further research and investment. Our calculations suggest that the recovery of metals like nickel and cobalt—demand for which is growing from their use in decarbonization technologies—could be as financially valuable to mineralization projects as the carbon credits they generate.

The importance of co-products means that we also need to understand local industry and industrial ecology opportunities

Does shipping olivine from Norway (where there is another large mine, powered by hydropower) break the carbon math for a project in Washington? Surprisingly, no. With a transport intensity of approximately 208 kg CO₂e / MT CO₂ stored, many scenarios using Norwegian olivine remained net-negative. This underscores a critical insight: grid intensity and reaction efficiency often outweigh transport distance. But project economics would say otherwise.

This study highlights the value of parameterized LCA tools in navigating the complexities of CDR design and development pathways. While models cannot unilaterally dictate site or scale—decisions dependent on regulations, markets and other factors—they validate reactor-based mineralization as a robust solution.

Whether leveraging local Twin Sisters olivine reserves or global supply chains, the path to high-quality carbon removal lies in optimizing industrial ecology: balancing scale with co-product demand, decarbonizing process energy and meeting regional priorities.

See the paper and download the tool at:

Footnotes

1Capture efficiency equals net emissions divided by 10.